Products

- Packaging Machinery[10]

- Sewing Machines[3]

- Plastic Cutting Machinery[7]

- Cleaning Equipment[10]

- Plastic Vacuum Forming Machinery[3]

- Spot Welders[10]

- Other Welding Equipment[5]

- Tube Welders[2]

- Plastic Product Making Machinery[10]

- Plastic Welders[10]

- Printing Machinery[4]

- Metal Processing Machinery Parts[1]

- Cleaning Equipment Parts[3]

- Ultrasonic Cleaners[10]

- Packaging Boxes[1]

- Paper Product Making Machinery[1]

- Bag Making Machinery[1]

- Nonwoven Machinery[1]

Contact Us

- Contact Person : Ms. Wang Helen

- Company Name : Shenzhen Keepleader Machinery Co., Ltd.

- Tel : 0086-755-84190358

- Fax : 0086-755-84719778

- Address : Guangdong,ShenZhen,Building RongXing,BanTian,LongGang District,ShenZhen, China.

- Country/Region : China

- Zip : 518129

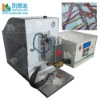

Battery Spot Welder,Battery Cell Spot Welder

Product Detailed

Related Categories:Spot Welders

Battery Spot Welder

energy Storage Spot Welder

Energy storage Spot Welder For Battery Cell

Battery Cell Spot Welder

CE

Battery Cell energy storage spot welder | Battery Cell energy storage spot welder | |||||

| Application | |||||

| Communications equipment: battery combination, cell phone batteries, cell phone hardwareElectronic Components: CRT devices, sensors, resistors, fuses, semiconductor componentsAppliance: metal piece to fix, heating pieceAutomobile making: flashing lights, relays, filamentsDigital Products: laptop computers, digital cameras, MP3 batteries, computer memory heads and so on.electromechanical devices: contactors, circuit breakers, motorsMetal Products: medical equipment, lamps, badge, headdress, jewelry and other aerospace, Precision metal parts, instrument, metal connectors, sensors, etc | |||||

| Character | |||||

| (single) double AC pulse energy storage welding, which is reliable for welding resultCPU control, high definition LED display 240*64, the operation is visual and be more precision128 user-defined welding procedures, all of them can be locked by managerState locking technology, which can avoid false triggeringThe unit can integrated into automatic production lineCan set pedal switch to detect the welding parts before power generatingCan set prepressing time before power dischargeRadio (RFI) and electromagnetic interference (EMI) protection Power box and welding section are separated, which is saferPneumatic and pedal control in one machine, which is more flexibleDischarge time can be set between pulse 1 and pules 2long, medium and short-pulse adjustable to fit fine welding | |||||

| Mainly parameter | |||||

| Rated power: 3.0 up 500watts/second (joule), the display screen can show the whole (maximum) energy percentage (%), the tolerance is 0.5%, the display screen is 0.1% up 0.5% in required energyStability of power box: changes in the nominal voltage supply of +/- 13%, the power box can keep the voltage of capacity band at set value of +/-0.25%Display screen: the display screen adopts 240*64 high definition LCD, is visible for debuggingCapacitor control circuit: when the voltage of error amplifier is over the required value to cut off charging circuit, one resistor connects at two sides of capacitor bank, by which let the voltage of capacitor bank work at required level, the dead zone of capacitor control circuit is about 0.6% of maximum voltageLine fault step-down: the is for safety purpose, when the power supply cut off suddenly, one resistor of voltage step-down automatic connects to release the power of capacitor bankIgnition circuit: Ignition requires an external account is closed or low-touch control logic circuit, inside filtering device can prevent electrical interference (RFI) triggered over ignitionPower supply: 220v, AC, 50/60HZ, 2635watts rechargeable, 35wattes as spare, When 230V, 2A CutoutWelding ignition lock: error amplifier output, when charging and discharging to prevent ignition circuit, which is helpful to prevent to ignition before capacitor charging and discharging, the welding ignition lock circuit can prevent defected welding effectProgrammable Prepressing time: combine with ignition welding head in the manual and automatic working mode without welding pressure, guarantee electrode is positioned well with welding parts before welding energy outputting, the prepressing time can be programmable (range:0.1 up 9.9 seconds) remote program selection: four monopole input: remote selection1-128 procedure; remote to prevent capacitor bank charging, when do remote program, the operation panel can be insteadValve drive output: can control electromagnetic valve of pneumatic welding head, 24VAC, 15A outputOutput pulse characteristic: at the side of power output, multiple a non-inductive load of 0.01 ohms, at both ends of it to measure pulse characteristics, to measure the rising time between zero amplitude and maximum point, to measure the pulse width at 10% amplitude point | |||||

| Pulse transformer | Capacitor bank | Rising time | Pulse width | Pulse amplitude | |

| Multiple(short) | 6000mfd | 1.7ms | 6.8ms | 9.5v | |

| series(long) | 6000mfd | 9.2ms | 2.7ms | 7.3v | |

| Welding speed: how many piece can be welded per minutes average when the machine work at rated status, | |||||

| Maximum energypercentage | Repeated weldingNos/minutes | Interruptedwelding Nos/minutes | |||

| 2% under | 166 | 240 | |||

| 25% | 109 | 118 | |||

| 50% | 71 | 82 | |||

| 100% | 40 | 42 | |||

| Specifications | |||||

| Model | KLM-250 | ||||

| Rated power | 3.0-250w/s | ||||

| Drive Form | Pedal | ||||

| Welding Current | 0-99 Adjust | ||||

| Electrode Diameter | optional | ||||

| Input Power | AC220± 10%/50Hz | ||||

| Welding Power | DC | ||||

| Electrode Travel Length | 15mm | ||||

| Max Welding Thickness | 0.2mm | ||||

| Overall dimension | 310mm*280*430mm | ||||

| Net weight | 97kg | ||||

Battery Spot Welder,Battery Cell Spot Welder

Other products