- Packaging Machinery[10]

- Sewing Machines[3]

- Plastic Cutting Machinery[7]

- Cleaning Equipment[10]

- Plastic Vacuum Forming Machinery[3]

- Spot Welders[10]

- Other Welding Equipment[5]

- Tube Welders[2]

- Plastic Product Making Machinery[10]

- Plastic Welders[10]

- Printing Machinery[4]

- Metal Processing Machinery Parts[1]

- Cleaning Equipment Parts[3]

- Ultrasonic Cleaners[10]

- Packaging Boxes[1]

- Paper Product Making Machinery[1]

- Bag Making Machinery[1]

- Nonwoven Machinery[1]

- Contact Person : Ms. Wang Helen

- Company Name : Shenzhen Keepleader Machinery Co., Ltd.

- Tel : 0086-755-84190358

- Fax : 0086-755-84719778

- Address : Guangdong,ShenZhen,Building RongXing,BanTian,LongGang District,ShenZhen, China.

- Country/Region : China

- Zip : 518129

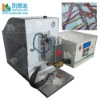

Ultrasonic Battery Anode Welding Machine,Lithium Battery Welding machine

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

Principle of ultrasonic metal welding | |

Ultrasonic metal welding machine is applied in Battery industries, the ultrasonic frequency is 20-40khz, ultrasonic energy is generated by high-frequency mechanical vibration, which is applied on the surface of welding parts in welding area under pressure (3kg-5kgs), the same metal or dissimilar metal of non-ferrous can be welded without heating and current, the only mechanical vibration is only repeating between the welding parts to form a solid combination | |

Character | |

Adopt advanced technology from USA, Microprocessor control, automatic frequency tuning, automatic current checking and phase frequency LED display keep the machine visible in operation and regulation Imported components, good performance in energy output Overcurrent protection and soft start can keep the machine safe High quality mould/Tooling can extend lifespan Easy installation and operation | |

Model | KLM-1224 |

Ultrasonic power | 1.2kw |

Ultrasonic frequency | 24khz |

Air supply | 7-8bat (kg/cm*2) |

Power supply | 220VAC,50HZ |

Maximum working pressure | 6kg/ cm*2 |

Minimum working pressure | 0.3kg/cm*2 |

Inlet connection | Quick coupling |

Welding time | 0.01s-10s (adjustable) |

Squeeze time | 0.02s-1s (adjustable) |

Frequency display | 00.0000-24.000hz |

Power option | 300w,600w,1200w |

Automatic frequency tuning | ±20HZ |

Protection system | Inside power tube self-protection 60+ |

EMI/EMC | qualified |

Cylinder diameter | 50mm |

Cylinder stroke | 20mm |

Welding head | Fillet welding |

Size of welding spot | 3*30mm |

Overall size | 438*280*329mm |

Net weight | 40kgs |

Packing size | 210*50*2000mm |

Ultrasonic Battery Anode Welding Machine,Lithium Battery Welding machine