Products

- Packaging Machinery[10]

- Sewing Machines[3]

- Plastic Cutting Machinery[7]

- Cleaning Equipment[10]

- Plastic Vacuum Forming Machinery[3]

- Spot Welders[10]

- Other Welding Equipment[5]

- Tube Welders[2]

- Plastic Product Making Machinery[10]

- Plastic Welders[10]

- Printing Machinery[4]

- Metal Processing Machinery Parts[1]

- Cleaning Equipment Parts[3]

- Ultrasonic Cleaners[10]

- Packaging Boxes[1]

- Paper Product Making Machinery[1]

- Bag Making Machinery[1]

- Nonwoven Machinery[1]

Contact Us

- Contact Person : Ms. Wang Helen

- Company Name : Shenzhen Keepleader Machinery Co., Ltd.

- Tel : 0086-755-84190358

- Fax : 0086-755-84719778

- Address : Guangdong,ShenZhen,Building RongXing,BanTian,LongGang District,ShenZhen, China.

- Country/Region : China

- Zip : 518129

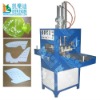

Hot Melt Welding Machine,Hot Fuse Welding

Product Detailed

Related Categories:Plastic Welders

Hot Melt welding Machine

Hot Plate welding Machine

Hot fuse welding machine

Plastic hot melt Welding

Hot moulding machine

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

| keywords | |

| Hot plate welding machineHot welding machineHigh frequency welding machineSpinning welding machineHot-Melt welding machineUltrasonic plastic welding machine | |

| Hot-Melt welding machine | |

| Character | |

| Easy to operate, and wide application.After welding up watertight, airtight effects of welding.For larger or irregular welding of the workpiece can be resolved.By man-machine interface with PLC computer control system, security and correct action.To linear guide bearing thermal model, high precision, quality guaranteed.Using hydraulic cushioning shock absorption system, noise minimal.Speed, the provincial labor, high efficiency, twice faster than traditional | |

| Function | |

| The products are large heating surface and the large face design, suitable for larger objects while the processing and multi-processing, light body, very convenient for transportation and resettlement, activities designed to replace the upper and lower mold clamping is more simple, a significant reduction in production costs and flexible use, a full range of products are high quality imported cylinder, chassis and high electrostatic spraying hard chrome plated table to make our products good looks, durable, all accessories are Taiwan, Japan, South Korea imports, quality and reliable; functional design respect, both electronic and electronic limit the buffer, | |

| Mainly application | |

| For home electrical products, musical instruments, stationery, toys, auto parts, electrical appliances, medicines containers, food, medical devices, cosmetics, sundry goods, spare parts and other plastic products and packaging supplies the welding process.Copper nails, screws implant Plastic welding, forming Riveting | |

| Parameter | |

| model | KLC-1600 |

| Available area | 400*300mm |

| Heat area | 360*200mm |

| Overall | 400*500*700mm |

| Net Weight | 120kg |

| Frequency | AC220 |

Hot Melt Welding Machine,Hot Fuse Welding

Other products