Products

- Packaging Machinery[10]

- Sewing Machines[3]

- Plastic Cutting Machinery[7]

- Cleaning Equipment[10]

- Plastic Vacuum Forming Machinery[3]

- Spot Welders[10]

- Other Welding Equipment[5]

- Tube Welders[2]

- Plastic Product Making Machinery[10]

- Plastic Welders[10]

- Printing Machinery[4]

- Metal Processing Machinery Parts[1]

- Cleaning Equipment Parts[3]

- Ultrasonic Cleaners[10]

- Packaging Boxes[1]

- Paper Product Making Machinery[1]

- Bag Making Machinery[1]

- Nonwoven Machinery[1]

Contact Us

- Contact Person : Ms. Wang Helen

- Company Name : Shenzhen Keepleader Machinery Co., Ltd.

- Tel : 0086-755-84190358

- Fax : 0086-755-84719778

- Address : Guangdong,ShenZhen,Building RongXing,BanTian,LongGang District,ShenZhen, China.

- Country/Region : China

- Zip : 518129

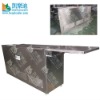

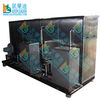

Multistage Ultrasonic Vapor Degreaser,Ultrasonic Cleaning machine

Product Detailed

Related Categories:Cleaning Equipment

Multistage Ultrasonic Vapor Degreaser

28khz Vapor Degreaser

Electronic Parts Vapor degreaser

CE Vapor Degreaser

Degreaser

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

Multistage ultrasonic vapor degreaser

| Four tank ultrasonic vapor degreaser | |

| Application | |

| Ultrasonic vapor degreaser is used for cleaning electronic components, the rosin of circuit board, heavy grease of precision mechanical parts, polishing wax, precision copper parts, aluminum zinc alloy, greasy hardware | |

| Character | |

| Imported vibrators IIE made in USAStainless steel cleaning tank, SUS304,2.0mm for thicknessImported air cooling unit made in USAOther electronics, made in Japan or South KoreaBuild-in condensing system, fully enclosed, by which to avoid solvent evaporationLiquid level sensor and alarm system for ensuring the machine work properlySolvent filtration and recycling system reduce the production costFast drying system to improve efficiencyAutomatic temperature control system | |

| Qualified Solvent | |

| Trichloroethylene, methyl chloroform and other organic solvents (non-flammable solvent) | |

| Cleaning process | |

| First class ultrasonic cleaning→second class ultrasonic cleaning→vapor cleaning→cooling and drying (automatic distillation solvent recovery and automatic recycling) | |

| mainly parameter | |

| Ultrasonic cleaning tank ( fist class and second class) | |

| inner cleaning tank | 300*320*340mm(L*W*H) |

| Vibration mode | Bottom |

| Vibrators number | 12pcs |

| Ultrasonic power | 600w |

| Ultrasonic frequency | 28khz |

| Heating power | 2kw |

| Heating mode | Heating board from outside |

| Temperature | 0 up 100 |

| Vapor cleaning tank | |

| Inner cleaning tank | 300*320*380mm |

| Heating power | 2kw |

| Heating mode | Heating tube into the water |

| Temperature | 0 up 110 |

| Distillation tank | |

| Inner cleaning tank | 300*320*390mm |

| Heating power | 2kw |

| Heating mode | Heating tube into the water |

| Temperature | 0 up 110 |

| Frozen system | |

| power | 3HP |

| Frozen height | 450mm |

| Turns of frozen pipes | 10-3/4 |

| General parameter | |

| Overall size | 2230*660*1170mm |

| Overall power | 11kw |

| Power supply | AC380V,50HZ |

Multistage Ultrasonic Vapor Degreaser,Ultrasonic Cleaning machine

Other products